This consolidates overhead cost information from multiple sources, including payroll, point-of-sale, billing and more. With a unified data set, generating financial statements and calculating accurate overhead rates is streamlined. So in summary, the overhead rate formula relates your indirect operating costs to production costs.

Operating Expenses Vs Overhead Expenses

If overhead costs rise rapidly, increasing overhead rates will make this clear. Let’s assume a company has overhead expenses that total $20 million for the period. If a job in work in process has recorded actual machine hours of 140 for the accounting period then the predetermined overhead applied to the job is calculated as follows. A predetermined overhead rate is calculated before the start of an accounting period.

Selecting an Estimated Activity Base

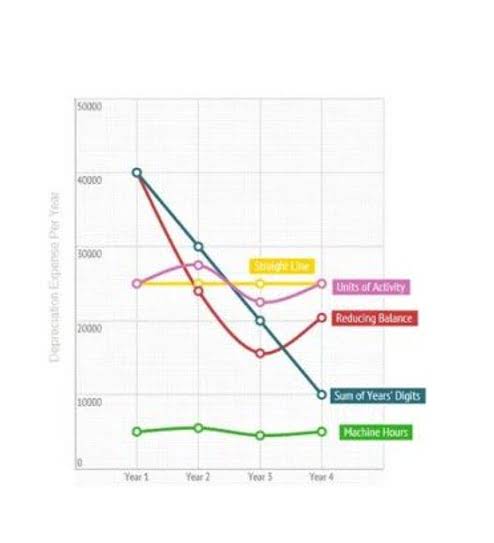

The difference between actual and applied overhead is later assessed to determine over- or under-application of overhead. We’ll outline the basic formulas used to calculate different types of overhead rates and provide overhead cost examples. Overhead expenses are generally fixed costs, meaning they’re incurred whether or not a factory produces a single item or a retail store sells a single product.

- As more and more products are produced, the greater the effect on profitability.

- However, the use of multiple predetermined overhead rates also increases the amount of required accounting labor.

- Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week.

- The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period.

- Using the Solo product as an example, 150,000 units are sold at a price of $20 per unit resulting in sales of $3,000,000.

- If costs rise above predetermined limits, action can be taken to reduce expenses.

Calculating Overhead Cost Per Unit

It is equal to the estimate overhead divided by the estimate production quantity. One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate. A business can calculate its actual costs periodically and then compare that to the predetermined overhead rate in order to monitor expenses throughout the year or see how on-target their original estimate was. This comparison can be used to monitor or how is sales tax calculated predict expenses for the next project (or fiscal year).

We can calculate predetermined overhead for material using units to be allocated. For example, we can use labor hours worked, and for calculating overhead for the store department, we can use the quantity of material to be used. Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision. However, the use of multiple predetermined overhead rates also increases the amount of required accounting labor. For this, you can take the average manufacturing overhead cost for the previous three months, and divide this by the machine hours in the current month. If you then find out later that in fact the actual amount that should have been assigned is $36,000 dollars, then the $4000 dollar difference should be charged to the cost of goods sold.

For example, overhead costs may be applied at a set rate based on the number of machine hours or labor hours required for the product. By using the predetermined rate product costs and therefore selling prices can be calculated quickly throughout the year without the need to wait for actual overheads to what is predetermined overhead rate be determined and allocated. In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. Finally, if the business uses material costs as the activity base and the estimated material costs for the year is 160,000 then the predetermined manufacturing overhead rate is calculated as follows.

As your business grows and becomes more complex, you can refine your methodology. Remember, even a rough predetermined rate is better than ignoring overhead entirely, which is a common mistake that leads to underpricing and cash flow problems. The manufacturing plant requires 1000 labor hours to manufacture 500 units of a specific product, which we assume as product X.

- Different methods are used to apply predetermined overhead rates based on the chosen cost driver.

- Management analyzes the costs and selects the activity as the estimated activity base because it drives the overhead costs of the unit.

- The same manufacturing plant also produces 1000 units of another product, which we call product Y, using 500 labor hours.

- Also, it’s important to compare the overhead rate to companies within the same industry.

- The goal is to have a more accurate understanding of the true cost of each product or service.

- Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor.

- The predetermined overhead rate is an estimated rate used to allocate overhead costs to products or jobs.

It’s essential to fully understand the allocation base and allocation rate or variance for the predetermined overhead rate. Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs. This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead costs incurred. Overhead rates refer to the allocation of indirect costs to the production of goods or services.

Suppose that X limited produces a product X and uses labor hours to QuickBooks Accountant assign the manufacturing overhead cost. The estimated manufacturing overhead was $155,000, and the estimated labor hours involved were 1,200 hours. The overhead rate helps businesses understand the proportion of indirect costs relative to direct costs. It can be used to allocate overhead when calculating product costs and profits. The overhead rate is a cost allocated to the production of a product or service. Overhead costs are expenses that are not directly tied to production such as the cost of the corporate office.